Rohstofflieferant und -hersteller für Industriemineralien, Chemikalien und Brennstoffe:

EKC.AG

Wir, die EKC.AG, sind ein global tätiger Rohstofflieferant mit Spezialisierung auf Energie-/Industrieressourcen und Chemikalien sowie dem dazugehörigen Risikomanagement und Logistik.

Neben Hochofenkoks, Gießereikoks, Anthrazit und Aluminiumhydroxid in sämtlichen Varianten handeln wir auch mit Industriemineralien und bieten unter anderem Chromerz Sand, Bauxit (roh und kalziniert), Schmelzmagnesit, Sintermagnesit, Graphit, Siliziumcarbide und Spinell. Dabei beliefern wir neben der Stahlindustrie, Feuerfestindustrie, Gießereien, Dämmstoff, Glas- und Siliziumindustrie auch Kunden aus der Keramik- sowie der Schleifmittelbranche. Bei den Chemikalien umfasst unser Produktportfolio: Aceton, Essigsäure und Borax.

Wir bieten unseren Kunden umfassenden technischen Support.

Hersteller der Silizium- und Ferro-Industrie profitieren bei der EKC.AG von kompetentem Service, einschließlich:

- Auswahl und Einstellung von Technologie und Ausrüstung für das Schmelzen

- Extra-Ofen-Raffinerie (komplettes Block-Management)

- Schmelzgießen und Arbeiten bis zum fertigen Produkt (komplettes Block-Management)

- Hilfsobjekte (komplettes Block-Management)

- Produktqualitätsmanagement

- Einrichtung von Laborarbeitsprozessen

- Qualitätsanalyse der Endprodukte

- Fertigungskontrolle

- SWOT-Analyse

- Qualitätsmanagementsystem für den gesamten Prozess von der Lieferung der Rohstoffe bis zum Endprodukt und der Qualitätszertifizierung

Wir verfügen über langjährige Erfahrung, enormes logistisches Potenzial, Premium-Qualität, Lieferzuverlässigkeit, dazugehöriges Risikomanagement sowie effiziente Schüttgutlogistik. Was können wir für Sie tun?

Mineralien

Für viele Produktions- und Herstellungsprozesse stellen Industriemineralien, Erze und Chemikalien mittlerweile unverzichtbare Grundstoffe dar. Egal ob in der Stahl- und Feuerfestindustrie, der Metallurgie, der Gießerei oder bei der Herstellung von Elektronik und Keramik – Mineralien sind aus diesen und vielen weiteren Segmenten nicht mehr wegzudenken.

Brennstoffe

Die Welt steht nie still. In der ständig wachsenden und sich wandelnden Welt steigt der Energiebedarf der Länder und der Unternehmen weltweit von Jahr zu Jahr immer weiter an. Moderne Hightech-Produktionen verlangen nach speziellen Kohleprodukten mit einem Höchstmaß an Reinheit. Wir bieten diese.

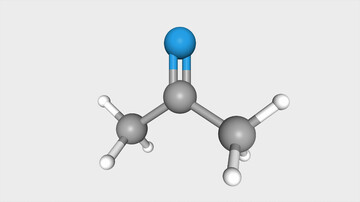

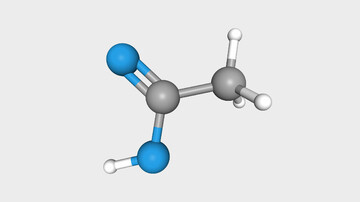

chemikalien

Die Existenz der meisten Alltagsgegenstände ist heute ohne Chemikalien nicht mehr vorstellbar.

Chemische Produkte werden in Kunststoffen, Lösungsmitteln, Weichmachern, Farben und Dichtstoffen sowie in der verarbeitenden Industrie eingesetzt. Zum Beispiel bei der Herstellung von Gummi, Textilien oder Waschmitteln.

In der Zahnmedizin, der pharmazeutischen Industrie, der Kosmetikindustrie und sogar in der Lebensmittelproduktion – ohne Chemie geht es nicht.

EKC.AG

Ihr Lieferant für Mineralien und Brennstoffe

Die Produktion und/oder Beschaffung der Rohstoffe und derer Anlieferung an unsere Kunden erfolgt bei uns mit stets gleichbleibender Qualität, zu marktgerechten Preisen und mit einwandfreier Logistik weltweit. Als international tätiger Rohstofflieferant für Industriemineralien und Brennstoffen verfügen wir über eigene Minen und Produktionen, sowie mehrere exklusiven Verkaufsrechte und langjährige Lieferverträge mit unseren Partnern aus Russland, Europa, Afrika, Asien und Süd-Amerika.

Neben dem Hauptsitz im unterfränkischen Würzburg ist unser Unternehmen auch in folgenden Städten präsent: Duisburg (DE), Rotterdam (NL), Moskau (RU), St. Petersburg (RU), Vyborg (RU), Vladivostok (RU), Ekaterinburg (RU), Tianjin (CN) und Güllük (TR). Außerdem verfügen wir weltweit über ein starkes Partnernetzwerk und bieten Ihnen somit eine stabile, verlässliche und langfristige Versorgung mit den nötigen Rohstoffen.

Unsere Mitarbeiter verfügen neben erstklassigen Branchenkenntnissen über langjährige Erfahrung in der Produktion, Aufbereitung, im Vertrieb und Handel sowie Transport von Industriemineralien und Energieressourcen.

Weitere Informationen zur ekc.ag - Ihr Lieferant für Mineralien und Brennstoffe

Wertschöpfungskette

Realisierte Rohstoffe in MT

1422000

Zurückgelegte Kilometer

2653000

Größte Einzelverschiffung

55.000

Anzahl der Minen/Partner

18